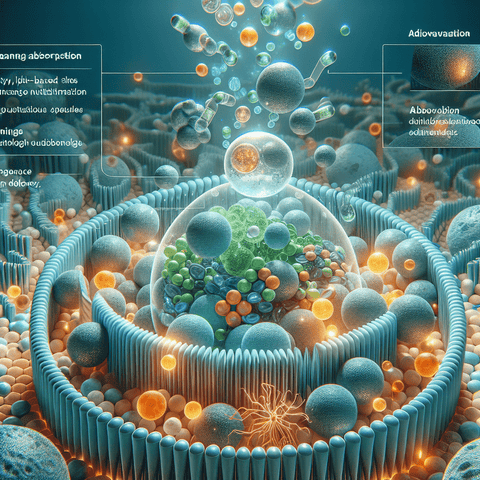

It describes liposomal supplements, which are formulated with tiny vesicles called liposomes. These spherical shells are constructed from phospholipid bilayers, similar to cell membranes, and can encase various substances within a protective, lipid-rich environment. This encapsulation creates a unique delivery system designed to blend seamlessly with finished products while emphasizing stability and compatibility. Advanced liposome technology involves precise control over vesicle size, lamellarity (single or multiple layers), and surface features. Techniques like microfluidic assembly, controlled hydration, extrusion, and careful purification enable the production of uniform particles with predictable properties. Surface modifications, such as pegylation or customized lipid blends, can influence the behavior of liposomal supplements in formulations, extending shelf life and ensuring consistent dispersion. Encapsulation within liposomal supplements provides a resilient environment for sensitive ingredients, shielding them from environmental factors and allowing for tailored release profiles. The lipid shell serves as a barrier against external stresses, while the internal cavity can house hydrophilic components, with the bilayer accommodating lipophilic substances. Ongoing research in liposome design explores how composition and processing choices impact stability, compatibility with other ingredients, and scalability for manufacturing. When evaluating liposomal supplements, it’s important to consider clear information about quality and manufacturing practices. Key indicators include the sourcing of lipids, compliance with good manufacturing practices (GMP), batch testing, and independent validation where available. Transparent labeling of liposome size distribution, total lipid content, and encapsulation efficiency helps in comparing products and understanding the technical features of liposomal supplements.